We generally use 3D Scanning as a tool to complete a larger project. This gives us an accurate model of objects that are otherwise difficult to measure. 2D CAD, 3D CAD, 3D Scanning, 3D Printing and design are part of our capabilities we can offer.

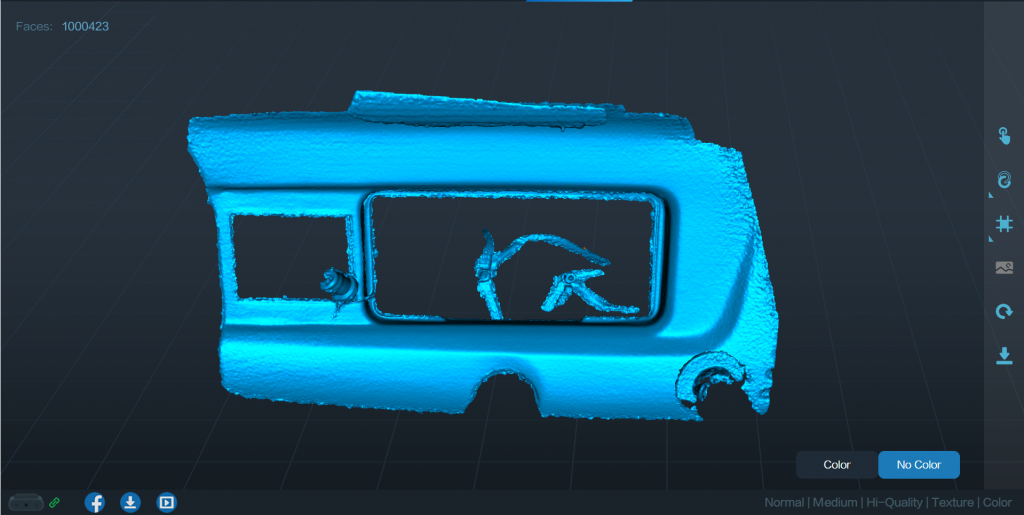

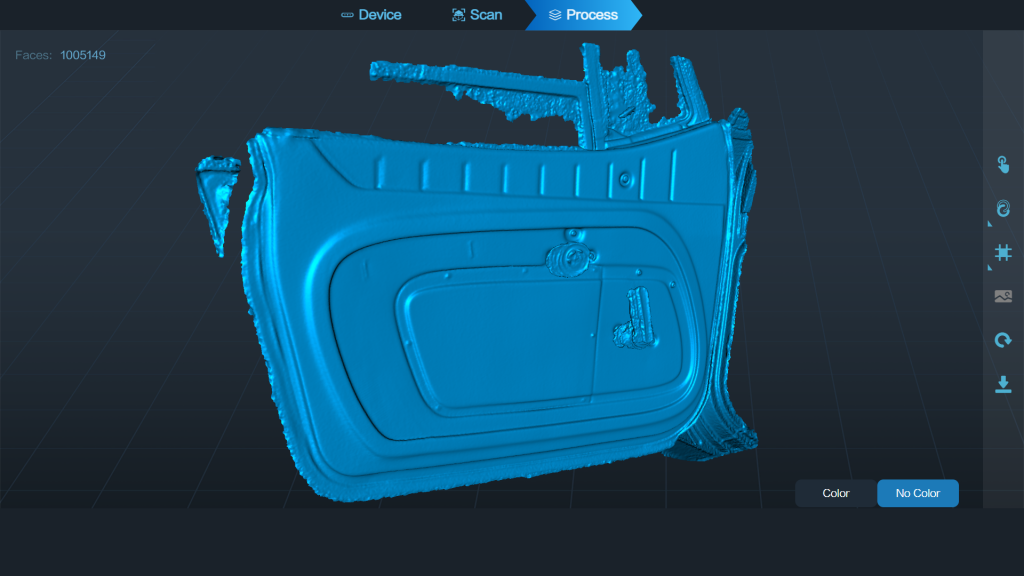

3D Scanning: This is the ability to scan small and medium parts, ranging from 6 inches to 6 feet in size. Some post processing is required for each scan, depending on part, size, shape, or surface finish. Contact us for more details.

2D CAD: This allows us to draw parts for laser and water jet cut files (DXF), process piping, layout and design or planning, and ‘as-built’ drawings of existing piping systems (DWG).

3D Modelling: We proudly use Autodesk Fusion 360 as a primary software for developing 3D Models for 3D Printing or CNC Machining. This allows us to test quick iteration prototypes with low up-front costs.